Expertise

Moulding and forming

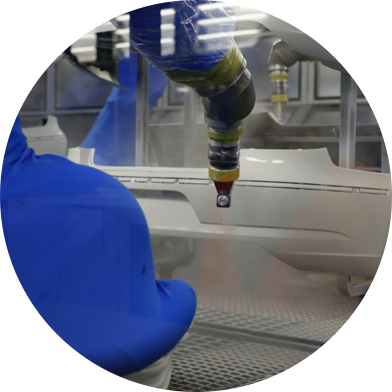

SMP is a leading expert in moulding and forming technology solutions. Our unique expertise in processing polymers is the base for the creation of products with highest quality standards and for our success since decades. Our huge injection-moulding facilities are located close to our customers' vehicle assembly plants across the globe, to ensure short supply distances and competitiveness.

Read more back to menu

back to menu